Ensuring Safety, Quality, and Regulatory Compliance in Advanced Medicine

Ensuring Safety, Quality, and Regulatory Compliance in Advanced Medicine

1. Introduction

GMP (Good Manufacturing Practice) plasmids are the backbone of cutting-edge biopharmaceutical development, serving as indispensable tools in gene and cell therapies (CGT), mRNA vaccines, and viral vector production. These high-purity DNA molecules are manufactured under rigorous standards to ensure safety, consistency, and compliance with global regulatory frameworks. As the demand for advanced therapies surges, GMP plasmids have emerged as critical starting materials, bridging the gap between laboratory innovation and patient-ready treatments. This article examines their pivotal role in safeguarding therapeutic efficacy and patient safety while addressing technical and regulatory challenges.

2. Ensuring Product Quality and Safety

A. Stringent Manufacturing Protocols

GMP plasmid production adheres to meticulously validated processes designed to eliminate contamination and ensure batch-to-batch consistency. Key protocols include:

- Single-Use Equipment: Minimizes cross-contamination risks during fermentation and purification .

- Animal-Free Raw Materials: Guarantees traceability and reduces immunogenicity risks in downstream applications .

- Endotoxin Control: Levels are maintained below 2 EU/mg through advanced chromatography and diafiltration techniques .

Suggested Figure: GMP plasmid production workflow: fermentation → lysis → purification → quality control testing.

B. Robust Quality Control (QC)

Comprehensive QC assays are mandated for GMP compliance:

- Identity Testing: Restriction digests and sequencing verify plasmid integrity .

- Purity Analysis: Capillary gel electrophoresis (CGE) quantifies supercoiled DNA content (>90%), a critical attribute for transfection efficiency .

- Sterility and Bioburden Testing: Ensures compliance with FDA/EMA guidelines for clinical use .

3. Enabling Advanced Therapeutic Applications

A. Viral Vector Manufacturing

GMP plasmids are essential for producing adeno-associated virus (AAV), lentivirus, and adenovirus vectors:

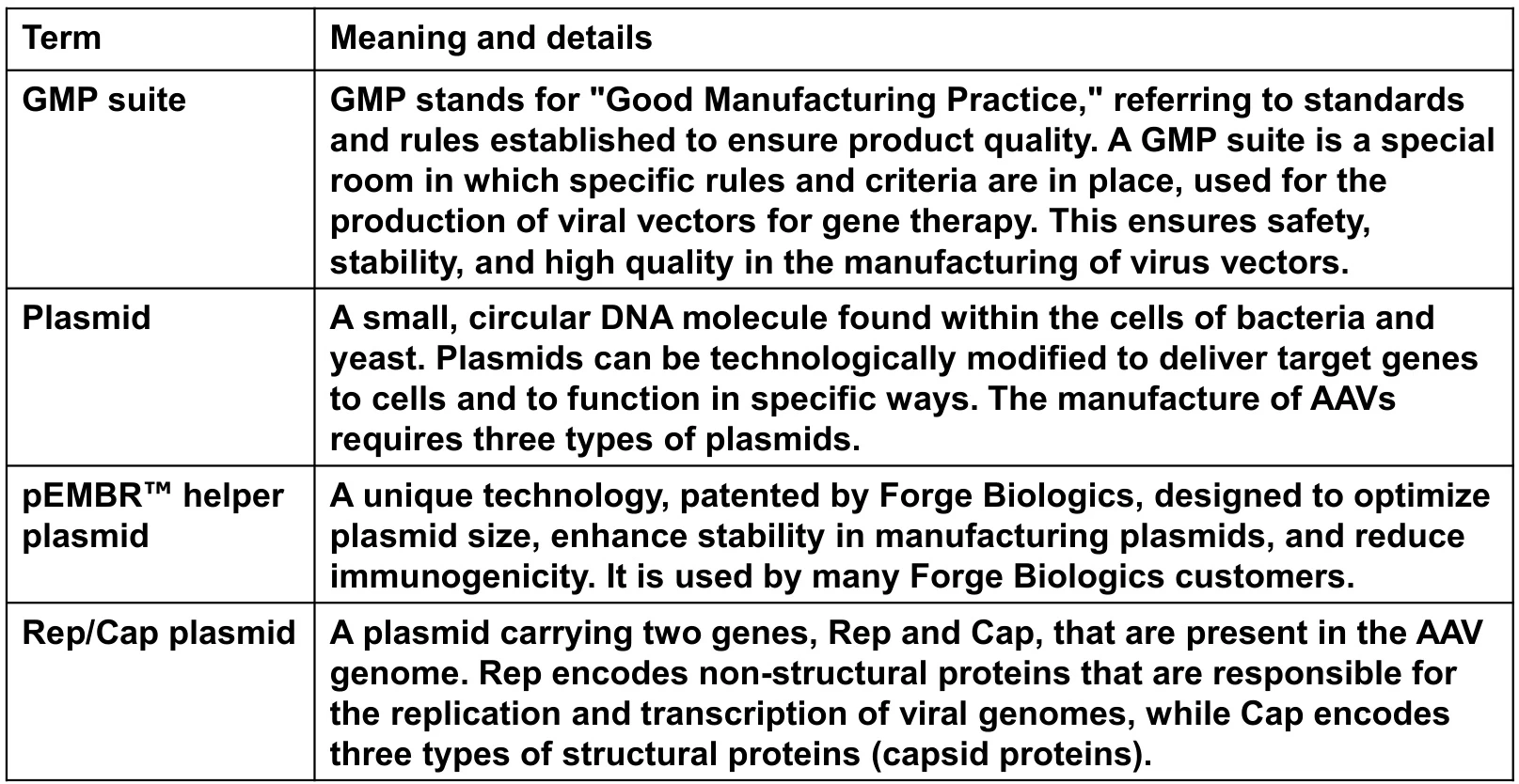

- AAV Production: Requires three plasmids—Rep/Cap (structural genes), helper (viral replication), and transgene (therapeutic payload). Proprietary systems like pEMBR™ enhance plasmid stability and reduce immunogenicity .

- Lentiviral Vectors: Used in CAR-T therapies, plasmids encode packaging genes (gag, pol) and envelope proteins (VSV-G) to ensure high-titer, clinical-grade vectors .

Suggested Figure: AAV vector assembly using GMP plasmids in HEK293 cells.

B. mRNA Vaccine Development

GMP plasmids serve as DNA templates for in vitro transcription (IVT) of mRNA:

- COVID-19 Vaccines: Pfizer-BioNTech and Moderna utilized GMP plasmids encoding the SARS-CoV-2 spike protein .

- Cancer Immunotherapy: Custom mRNA vaccines targeting tumor neoantigens rely on plasmid-derived sequences .

C. Direct Gene Therapy

Naked or lipid-complexed GMP plasmids are administered to treat genetic disorders:

- Duchenne Muscular Dystrophy: Plasmid-mediated dystrophin gene delivery restores muscle function in preclinical models .

- DNA Vaccines: Intramuscular injection of plasmids encoding antigens (e.g., Zika virus prM-E) induces potent immune responses .

4. Regulatory Compliance and Global Standards

A. EMA and FDA Guidelines

- EMA Requirements: Plasmids classified as starting materials must adhere to GMP principles, with validated processes for cell banking, fermentation, and purification .

- FDA Oversight: ICH Q7 and 21 CFR Part 211 govern facility design, environmental monitoring, and aseptic filling .

B. Phase-Appropriate Strategies

- Preclinical: High-Quality (HQ) or “GMP-like” plasmids suffice for toxicology studies .

- Clinical/Commercial: Full GMP compliance is mandatory, requiring Qualified Person (QP) certification for EU market release .

Suggested Figure: Regulatory roadmap for GMP plasmids: preclinical → Phase I/II → Phase III → commercial.

5. Overcoming Manufacturing Challenges

A. Scalability and Cost

- Fermentation Optimization: High-density E. coli cultures in 2,000L bioreactors improve yield but require precise pH and temperature control .

- Purification Bottlenecks: Multi-step chromatography accounts for 60% of production costs, driving demand for continuous processing systems .

B. Technological Innovations

- Antibiotic-Free Selection: Auxotrophic bacterial strains eliminate antibiotic resistance genes, enhancing safety .

- AI-Driven Process Optimization: Machine learning predicts ideal fermentation conditions, reducing batch failures .

6. Future Directions and Industry Impact

A. Synthetic Biology Integration

- Orthogonal Systems: Engineered plasmids with species-specific replication origins enable synthetic microbial consortia for biomanufacturing .

- DNA-Based Data Storage: Microsoft’s molecular archive prototypes use GMP plasmids to encode 1 exabyte of data per gram .

B. Sustainability Initiatives

- Green Chemistry: Solvent-free purification and renewable energy-powered facilities align with ESG goals .

Data Source: Publicly available references.

Contact: chuanchuan810@gmail.com