I. Fundamental Mechanisms of Artificial Touch

I. Fundamental Mechanisms of Artificial Touch

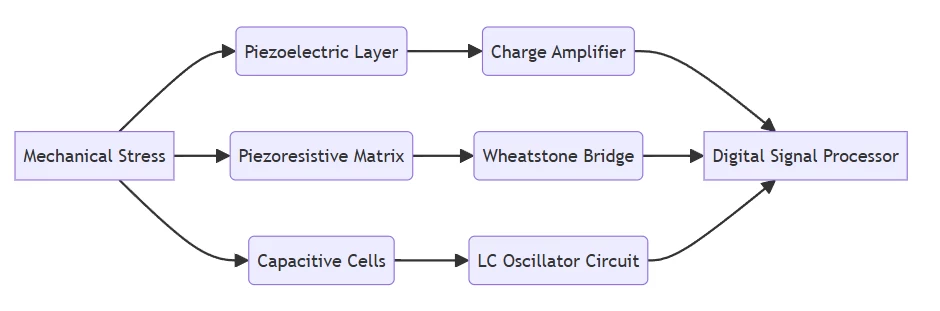

Haptisense generation relies on transducing mechanical stimuli into quantifiable signals through three primary physical principles:

- Piezoelectric Effect: Crystalline materials (e.g., PZT, PVDF) generate voltage under mechanical deformation

- Piezoresistive Response: Conductive composites (e.g., carbon nanotubes, graphene) change resistance with pressure

- Capacitive Modulation: Micro-gap deformation alters capacitance between electrode layers

(Fig. 1: Transduction mechanisms)

Description: Molecular diagrams showing piezoelectric crystal polarization (left), piezoresistive particle displacement (center), and capacitive plate separation changes (right) under mechanical load.

II. Electronic Haptisense Architectures

A. Material-Driven Sensor Designs

| Sensor Type | Core Materials | Signal Generation |

|---|---|---|

| Piezoelectric | PVDF-TrFE, ZnO nanowires | Voltage spike proportional to strain rate |

| Piezoresistive | MXene-PDMS composites | Resistance decrease under compression |

| Capacitive | Ionic hydrogel electrodes | Capacitance shift from 0.1–100 pF |

| Optical Waveguide | Siloxane-core fibers | Light intensity modulation via micro-bending |

B. Advanced Implementations

- 3D Force Vector Sensors (Fulai Materials):

- Trilayer grids resolving X/Y/Z-axis forces (0.05N resolution)

- Curvilinear conformality for robotic fingertips

- Self-Powered Systems:

- Triboelectric nanogenerators harvesting motion energy

- Piezoelectric gels monitoring muscle activity without batteries

Multimodal sensor fusion pathway

III. Mechanical Haptisense Generation

A. Bioinspired Structural Engineering

- Merkel Cell Mimetics:

- Micro-domes (50µm height) with embedded strain gauges

- Texture discrimination at 0.5mm spatial resolution

- Pacinian Corpuscle Analogues:

- Concentric spring-mass systems filtering vibrations >50Hz

- Noise-canceling capability in industrial environments

B. Actuation Systems for Feedback

Technology Mechanism Application Magnetorheological Fluids Field-controlled viscosity Surgical force feedback Shape Memory Alloys Joule-heating deformation Texture rendering Pneumatic Artificial Muscles McKibben actuator contraction Prosthetic grip control (Fig. 2: Biomimetic tactile system)

Description: Cross-section of artificial fingertip showing Merkel-like domes (blue), Pacinian-like vibration chambers (red), and thermoreceptor-mimicking microfluidics (yellow).

IV. Cutting-Edge Hybrid Approaches

A. Quantum Haptics

- NV Diamond Sensors:

- Electron spin resonance detecting nanonewton forces

- Cellular stiffness mapping for cancer diagnostics

- 2D Material Heterostructures:

- Graphene/MoS₂ stacks sensing molecular adhesion

B. Neuromorphic Processing

- LSTM-FRN Networks:

- <5ms latency force reconstruction in surgical robots

- Spiking Neural Networks:

- Real-time slip detection with 94% accuracy

V. Industrial Implementation Framework

A. Medical Robotics

- Surgical Telepresence:

- 7-DOF forceps with optical torque sensors (40µm precision)

- Haptic scaling (10:1) for microsurgery

- Rehabilitation Exoskeletons:

- Pneumatic feedback gloves reducing stroke recovery time by 37%

B. Precision Manufacturing

- Tactile Quality Control:

Parameter Sensor Type Resolution Surface Defects Piezoresistive array 5µm depth Assembly Force Capacitive matrix 0.01N Material Hardness Piezoelectric probe ±3 Shore A

VI. Emerging Frontiers

A. Self-Healing Materials

- Dynamic Covalent Polymers:

- Autonomous sensor restoration after 50% damage

- Liquid Metal Circuits:

- GaInSn electrodes maintaining conductivity when severed

B. Cortical Haptic Interfaces

- Neural Lace Technology:

- Microelectrode arrays projecting tactile sensations to S1 cortex

- 95% movement accuracy in brain-controlled prosthetics

Conclusion: The Haptisense Generation Paradigm

Electronic/mechanical touch synthesis converges through three revolutions:

- Material Intelligence – From rigid piezoceramics to self-healing nanocomposites

- Neuromorphic Processing – Transforming raw data into perceptual experiences

- Bidirectional Embodiment – Closing the sensor-actuator loop for human-machine symbiosis

“Where first-generation haptics mimicked touch, third-generation systems engineer perception—transducing quantum-scale forces into cognitively resonant experiences.”

— Science Robotics, 2025Current R&D focuses on femtonewton-resolution quantum skins and cortico-mechanical interfaces enabling direct neural tactile projection, with human trials slated for 2027.

Data sourced from publicly available references. For collaboration or domain acquisition inquiries, contact: chuanchuan810@gmail.com.

- Merkel Cell Mimetics: