From Viral Vector Production to DNA Vaccines: A Multifaceted Tool for Advanced Medicine

From Viral Vector Production to DNA Vaccines: A Multifaceted Tool for Advanced Medicine

1. Introduction

GMP (Good Manufacturing Practice) plasmids are the cornerstone of modern biopharmaceutical manufacturing, ensuring the safety, consistency, and regulatory compliance of therapeutic products. These high-purity DNA molecules are indispensable across gene and cell therapies, mRNA vaccines, and viral vector production. By adhering to stringent quality controls, GMP plasmids enable scalable and reproducible manufacturing of life-saving treatments. This article explores their pivotal roles in advancing precision medicine.

2. Viral Vector Manufacturing

A. Adeno-Associated Virus (AAV) Production

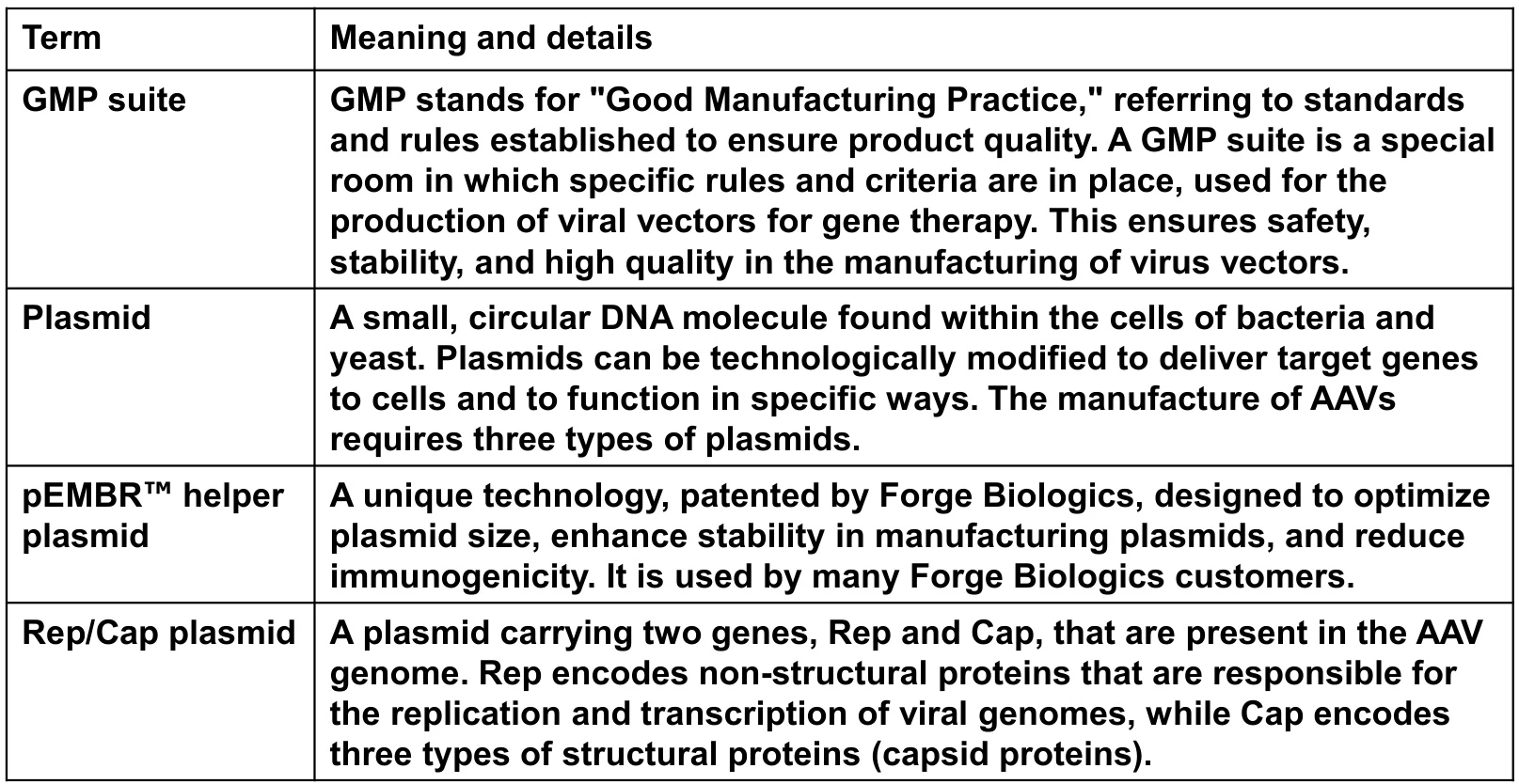

GMP plasmids are critical for generating AAV vectors, widely used in gene therapy due to their low immunogenicity and tissue specificity. AAV production requires three plasmids:

- Rep/Cap Plasmid: Encodes replication (Rep) and capsid (Cap) proteins essential for viral assembly.

- Helper Plasmid: Provides adenoviral genes (e.g., E4, VA RNA) for replication.

- Transgene Plasmid: Contains the therapeutic gene flanked by inverted terminal repeats (ITRs).

Proprietary plasmid systems, such as pEMBR™, optimize stability and reduce immunogenicity during large-scale AAV manufacturing.

Suggested Figure: AAV production workflow using GMP plasmids: transfection of HEK293 cells → viral harvest → purification.

B. Lentiviral and Adenoviral Vectors

Lentiviral vectors (e.g., for CAR-T therapies) rely on GMP plasmids encoding:

- Packaging genes (gag, pol, rev).

- Envelope glycoproteins (e.g., VSV-G).

- Therapeutic transgenes.

These plasmids ensure high-titer, clinical-grade vectors for oncology and genetic disorders.

3. mRNA Vaccine and Therapeutic Development

GMP plasmids serve as DNA templates for in vitro transcription (IVT) of mRNA. Key applications include:

- COVID-19 Vaccines: Pfizer-BioNTech and Moderna vaccines used GMP plasmids encoding the SARS-CoV-2 spike protein.

- Cancer Immunotherapy: Personalized mRNA vaccines targeting neoantigens are synthesized from plasmid DNA.

- Self-Amplifying RNA (saRNA): Plasmid-derived saRNA vaccines achieve higher antigen expression with lower doses.

Suggested Figure: mRNA production workflow: plasmid linearization → IVT → lipid nanoparticle (LNP) encapsulation.

4. Gene and Cell Therapies

A. Gene Editing Tools

- CRISPR-Cas9: GMP plasmids deliver Cas9 and guide RNA (gRNA) for ex vivo editing of hematopoietic stem cells (e.g., treating sickle cell anemia).

- Base Editors: Plasmid-encoded adenine or cytosine deaminases enable precise single-nucleotide modifications.

B. CAR-T Cell Engineering

GMP plasmids encode chimeric antigen receptors (CARs) and safety switches (e.g., HER2t), enabling scalable production of CAR-T therapies for leukemia and lymphoma.

Suggested Figure: CAR-T cell manufacturing: plasmid transfection → T-cell activation → expansion.

5. DNA Vaccines

Direct administration of GMP plasmids induces immune responses against encoded antigens. Examples include:

- Zika Virus Vaccines: Plasmid DNA encoding viral prM-E proteins elicits neutralizing antibodies.

- Oncology: Intramuscular injection of plasmids expressing tumor-associated antigens (e.g., NY-ESO-1) activates cytotoxic T cells.

Suggested Figure: Mechanism of DNA vaccines: plasmid uptake by dendritic cells → antigen presentation → T-cell activation.

6. Emerging Applications

A. Non-Viral Gene Delivery

GMP plasmids complexed with lipid nanoparticles (LNPs) or electroporation devices enable in vivo gene transfer for monogenic diseases (e.g., Duchenne muscular dystrophy).

B. Synthetic Biology

Engineered plasmids with orthogonal replication origins support synthetic microbial consortia for biomanufacturing therapeutics.

7. Challenges and Innovations

A. Scalability and Cost

Large-scale plasmid production faces bottlenecks in fermentation yield and endotoxin removal. Innovations like single-use bioreactors and AI-driven process optimization enhance throughput and reduce costs.

B. Regulatory Compliance

Phase-appropriate GMP standards (e.g., ICH Q7) require rigorous documentation, including plasmid sequence verification and residual host DNA quantification.

Data Source: Publicly available references.

Contact: chuanchuan810@gmail.com