haptisense.com

I. Defining the Haptic Sensory Architecture

Haptic perception in teleoperation constitutes a bidirectional sensory-motor loop integrating:

- Cutaneous Sensing: Pressure/texture/temperature detection via artificial mechanoreceptors

- Kinesthetic Feedback: Force/torque transmission through exoskeletal systems

- Cognitive Integration: Multimodal fusion with visual data for environmental cognition

(Fig. 1: Bio-inspired haptic pathway)

Description: Neuromorphic diagram showing artificial Merkel cells (blue) and Pacinian corpuscles (red) transmitting signals via neural networks to kinesthetic actuators (gold), replicating human sensory-motor integration.

II. Core Functions in Teleoperation Workflows

A. Environmental Perception Enhancement

Overcoming visual limitations through real-time tactile mapping:

- Visual Occlusion Compensation:

- Continuous object-state monitoring during grasping when cameras are obstructed

- Material Identification:

- Capacitive sensor arrays detect surface microgeometry with 5µm resolution

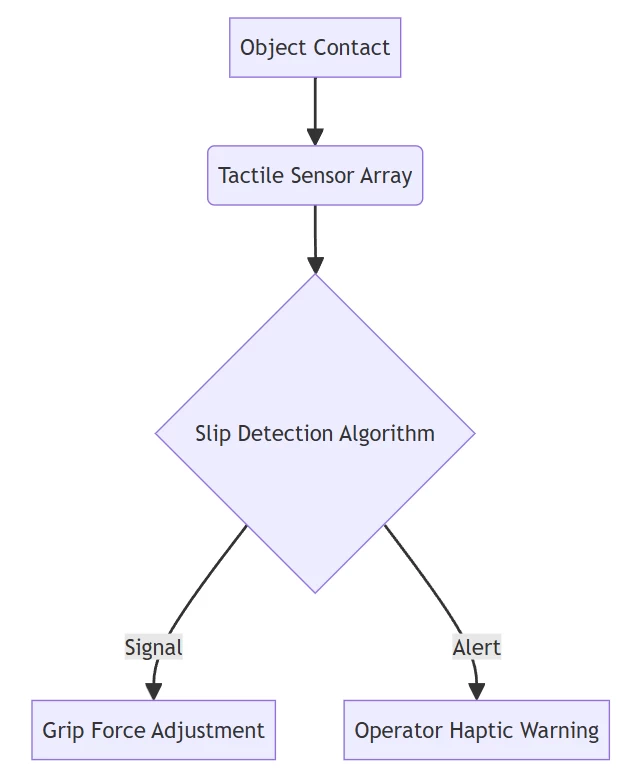

- Slippage Prevention:

- Vibrotactile alerts trigger 300ms reflex responses in robotic grippers

Real-time anti-slip control loop

B. Force Modulation Precision

Parameter Human Hand Haptic-Enhanced Robot Force Resolution 0.1N 0.05N Pressure Sensing 10kPa-1MPa 1kPa-2MPa Response Latency 50ms <20ms Performance benchmarks of modern systems C. Operator Immersion & Control

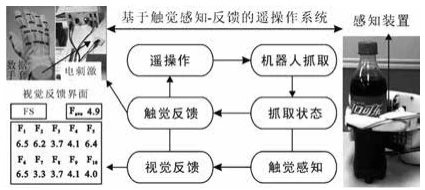

Bilateral haptic interfaces create embodied operation experience:

- Electrotactile Feedback:

- Spatial force mapping onto operator’s fingertips

- Exoskeletal Force Feedback:

- Magnetorheological actuators deliver 100N resistive forces

- Proprioceptive Synchronization:

- Muscle memory integration via SEMG bio-signals

(Fig. 2: Haptic control interface)

Description: Operator wearing exoskeletal gloves with embedded electrotactile actuators (blue zones), receiving real-time force feedback while controlling robotic manipulators.

III. Cutting-Edge Implementation Frameworks

A. Military/Industrial Systems

- Haption Virtuose 6D:

- 6-degree-of-freedom force feedback for heavy machinery teleoperation

- WAM Robotic Arms:

- X/Y/Z axis + yaw/pitch/roll torque feedback for nuclear maintenance

B. Medical Robotics

- Surgical Telepresence:

- 40µm precision during vitreoretinal operations via haptic scaling

- Rehabilitation Exoskeletons:

- Stroke patients show 37% faster motor recovery with tactile biofeedback

C. Extreme Environment Applications

- Deep-Sea Exploration:

- Submersible manipulators with pressure-adaptive tactile skins

- Space Robotics:

- Torque-controlled lunar regolith sampling for Artemis missions

IV. Technological Innovations Driving Progress

A. Advanced Sensor Technologies

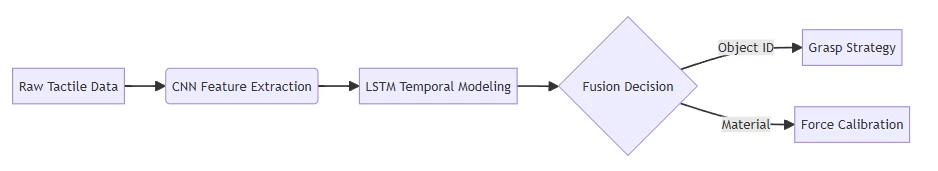

Sensor Type Mechanism Advantage Capacitive Microarrays Elastic micro-needle deformation 400 units/cm² resolution Optical Waveguides Light refraction changes 0.1µm texture detection Piezoresistive FSRs Conductive polymer compression Low-cost industrial integration B. AI-Powered Haptic Processing

Real-time tactile intelligence pipeline

V. Critical Challenges & Emerging Solutions

A. Technical Barriers

- Sensory-Bandwidth Mismatch:

- Human tactile channel capacity: 10,000 bits/sec vs. current systems: 1,200 bits/sec

- Cross-Modal Latency:

-

150ms visuo-haptic delay causes operator dizziness

-

B. Next-Generation Approaches

- Tactile Neuromorphics:

- Memristor-based chips reducing processing latency to 5ms

- Quantum Tactile Sensors:

- Diamond NV centers enabling nanoscale magnetic field detection

- Haptic Brain-Computer Interfaces:

- Direct cortical stimulation bypassing peripheral nerves

Conclusion: The Haptic Intelligence Paradigm Shift

Teleoperation systems are evolving through three haptic-enabled revolutions:

- Perceptual Expansion: Overcoming visual limitations via multimodal sensing

- Embodied Control: Creating neurocognitive operator-robot symbiosis

- Environmental Dialogue: Enabling machines to “feel” material properties

“Where traditional robotics interacts with environments, haptic-enhanced systems converse with them – transforming brute-force manipulation into nuanced physical dialogue.”

— IEEE Robotics & Automation Magazine, 2025Current R&D focuses on self-healing tactile skins for extreme environments and haptic digital twins enabling operator training in metaverse environments, with field deployment expected by 2027.

Data sourced from publicly available references. For collaboration or domain acquisition inquiries, contact: chuanchuan810@gmail.com.

- Electrotactile Feedback:

- Vibrotactile alerts trigger 300ms reflex responses in robotic grippers