I. Biological Blueprint: The Neuro-Mechanical Foundation

I. Biological Blueprint: The Neuro-Mechanical Foundation

Human tactile perception operates through specialized mechanoreceptors that convert mechanical stimuli into neural signals:

- Merkel Cells: Detect static pressure/texture via slow-adapting responses

- Pacinian Corpuscles: Sense high-frequency vibrations through rapid adaptation

- Ruffini Endings: Monitor skin stretch/deformation

- Meissner Corpuscles: Track motion/slip events

(Fig. 1: Biological-to-artificial transduction mapping)

Description: Comparative histology showing human glabrous skin receptors (left) alongside artificial sensor analogs (right) with signal processing pathways.

II. Core Transduction Mechanisms

A. Piezoresistive Principle

Fundamental Physics:

R = ρL/A → ΔR/R₀ = GF·εWhere resistivity (ρ) changes under mechanical strain (ε), with GF representing Gauge Factor .

Implementation:

- Conductive nanocomposites (graphene/MXene-PDMS) deform under pressure

- Interparticle distance alterations modify electron tunneling paths

- Resistance decreases proportionally to applied force

Advantages:

- High sensitivity (GF > 50)

- Simple signal conditioning

- Low-cost manufacturing

B. Capacitive Sensing

Operating Principle:

C = ε₀εᵣA/d → ΔC ∝ 1/ΔdCapacitance changes via:

- Electrode separation distance variation (parallel plate)

- Dielectric constant shifts (interdigital electrodes)

Design Innovations:

- Micro-structured dielectrics enhance sensitivity

- Ionic hydrogel electrodes enable stretchability

- 3D architectures for multi-axis force detection

C. Piezoelectric Effect

Physical Basis:

Q = d·FCharge generation (Q) proportional to applied force (F) via piezoelectric coefficient (d) .

Material Systems:

Material d₃₃ (pC/N) Application PZT 190-600 High-fidelity vibration sensing PVDF -20 to -30 Flexible pressure mapping AlN 5.6 MEMS integration Signal Challenges:

- High-impedance output requires charge amplifiers

- Temperature sensitivity requires compensation algorithms

D. Triboelectric Sensing

Working Model:

Vₒₚₑₙ = σ·d/(ε₀εᵣ)Surface charge separation (σ) generates voltage during contact-separation cycles .

Implementation Modes:

- Vertical contact-separation

- Lateral sliding

- Single-electrode configuration

Material Pairings:

- PTFE (electron acceptor) vs. Nylon (electron donor)

- Graphene-PDMS composites for enhanced output

E. Magnetic & Optical Systems

Magnetic Transduction:

- Halbach arrays enable 3D force decoupling

- Magnetostrictive materials change permeability under stress

Optical Waveguides:

- Micro-deformations alter light transmission paths

- CCD/CMOS sensors capture intensity/spatial shifts

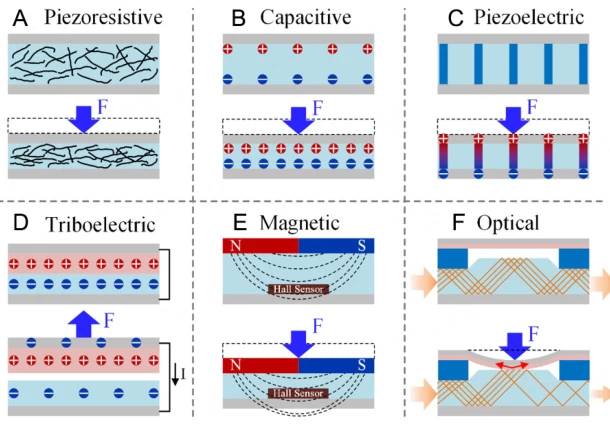

(Fig. 2: Cross-sectional sensor schematics)

Description: Annotated diagrams showing material layers and working principles for all six sensor types with signal output waveforms.

III. Advanced Signal Processing Architectures

A. Neuromorphic Processing

B. Machine Learning Integration

- Convolutional Neural Networks: Texture classification from spatial patterns

- LSTM Networks: Slip prediction from temporal vibration sequences

- Bayesian Optimization: Adaptive exploration in robotic palpation

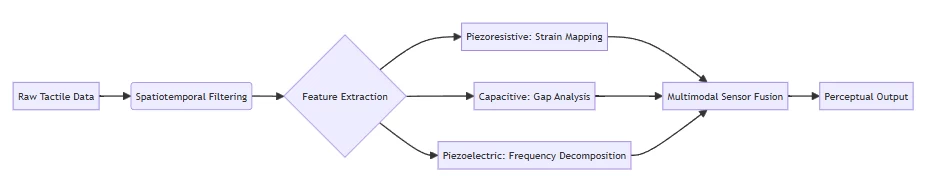

(Fig. 3: Tactile intelligence pipeline)

Description: Data flow from sensor arrays through noise filtering, feature extraction, and neural network processing to actionable outputs.

IV. Cutting-Edge Implementation Paradigms

A. Multi-Axis Force Decoupling

Magnetic Solution:

- Orthogonal Halbach arrays create directional field gradients

- 3D Hall sensors resolve Fx/Fy/Fz independently

- Eliminates complex mechanical structuring

Capacitive Approach:

- Tetrahedral electrode configurations

- Finite element modeling for force vector reconstruction

B. Hyper-Resolution Techniques

- Signal Overlap Utilization:

- Crosstalk between adjacent taxels becomes data source

- Super-resolution algorithms achieve 400% resolution enhancement

- Quantum Sensing:

- NV-center diamond probes detecting nanonewton forces

V. Application-Specific Implementations

A. Robotic Manipulation

Function Sensor Type Performance Metric Slip Prevention Piezoelectric 94% detection accuracy @ 5ms latency Texture Recognition Capacitive array 87% classification across 200 materials Grasp Force Control Piezoresistive 0.01N resolution B. Medical Diagnostics

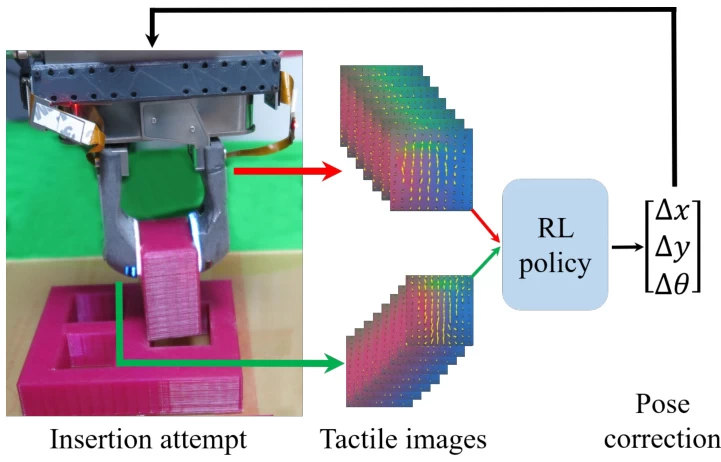

- Tactile RL Policies:

def insertion_policy(tactile_image): Δx, Δy, Δθ = RL_model.predict(tactile_image) execute_pose_adjustment(Δx, Δy, Δθ)Autonomous catheter guidance using tactile feedback

- Tumor Palpation:

- Piezoelectric PVDF arrays mapping tissue stiffness gradients

Conclusion: The Tactile Intelligence Frontier

Tactile sensing technology converges through three evolutionary vectors:

- Material Intelligence – From monolithic piezoceramics to self-healing nanocomposites

- Processing Revolution – Transitioning from analog circuits to neuromorphic computing

- Functional Convergence – Combining multiple principles in unified architectures

“Where first-generation sensors mimicked biological touch, third-generation systems transcend it—converting atomic-scale interactions into machine-understandable semantics.”

— Science Robotics, 2025Emerging R&D focuses on cortico-tactile interfaces for direct neural integration and quantum-elastic sensors reaching femtonewton resolution, with human trials projected by 2027.

Data sourced from publicly available references. For collaboration or domain acquisition inquiries, contact: chuanchuan810@gmail.com.

- Tumor Palpation: